What are the Plastic Recycling Stages?

November 29, 2023

Plastic materials are highly functional and durable, and have a wide range of uses. Their flexibility, heat and insulation properties and affordable prices make plastic products more attractive. However, one of the biggest advantages of plastic materials is that they can remain intact for a long time with minimal harm to the environment through recycling after use. Different methods are being developed to ensure that especially recycled plastic crate products do not harm the environment, and recycling methods have an extremely important place in this field. Recycling enables plastic materials to be reused after use without harming the environment.

How to Recycle Plastics?

This both serves the purpose of protecting natural resources and provides economic benefits by reducing costs. With the development of technology, various methods have emerged for recycling plastic cases. Recycling plastic materials is considered one of the cleanest and most effective solutions. Plastic is used in many products in many areas of our daily life, from our homes to our workplaces and public spaces. For this reason, plastic materials that go through recycling processes are made suitable for use in daily life again. This effort both contributes to the protection of the environment and contributes to a more sustainable future by reducing the impact of plastics.

Collection of Plastics

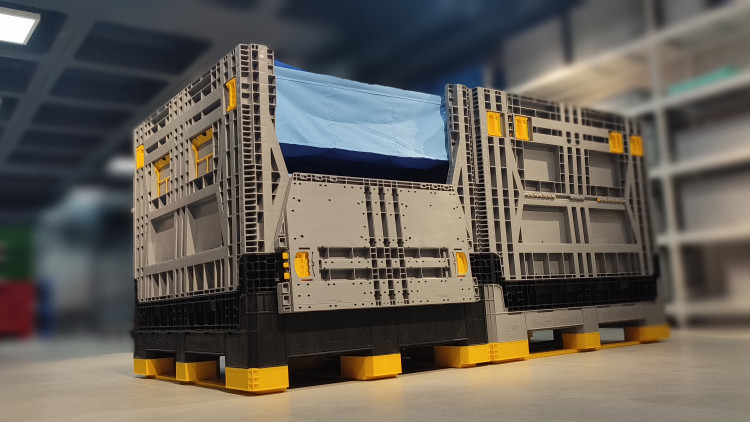

Used plastic bags, plastic bottles, packaging materials and other plastic products are often thrown away. These wastes are included in the recycling process through separation processes. In addition, they are collected by users by throwing them into containers allocated for recycling purposes.

Classification of Plastics

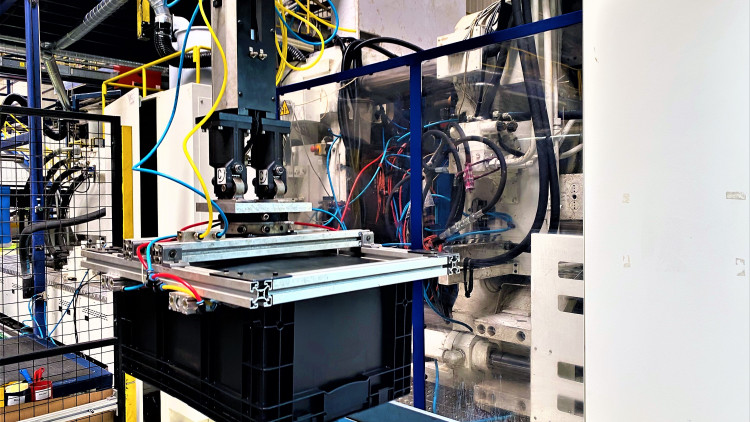

The collected plastics are processed with specialized machines during the classification stage. These machines are used to distinguish and identify different types of plastic. In this way, different types of plastic are separated from each other, making a more effective recycling process possible.

Disintegration of Plastics

After plastics are classified according to their types, they are broken into small pieces to make them more processable. At this stage, waste plastic materials are broken into pieces using crushing machines. Plastic materials are reduced in size thanks to devices such as crushers, grinders, shredders and crushers. The pieces obtained as a result of this process are called "bran".

Cleaning Plastics

In order to obtain higher quality products from pulverized plastic materials and to minimize quality loss, it is necessary to remove foreign substances such as adhesives, labels and dirt. For this purpose, dirt and labels are cleaned by spraying hot water on plastic materials in the washing pools. This step ensures that the products are free of dirt and labels. After the cleaning process, the materials are dried in dryers at appropriate temperatures. The moisture content is balanced depending on the type of plastic.

Melting of Plastic

After the shredding, cleaning and drying steps are completed, the plastic materials are melted. Plastics are melted, liquefied and fused in machines at temperatures suitable for their intended use. At this stage, the melted plastics are then cooled and converted into granule form. These granules are stored for reuse in plastic production.