What is Plastic Case Raw Material?

September 25, 2023

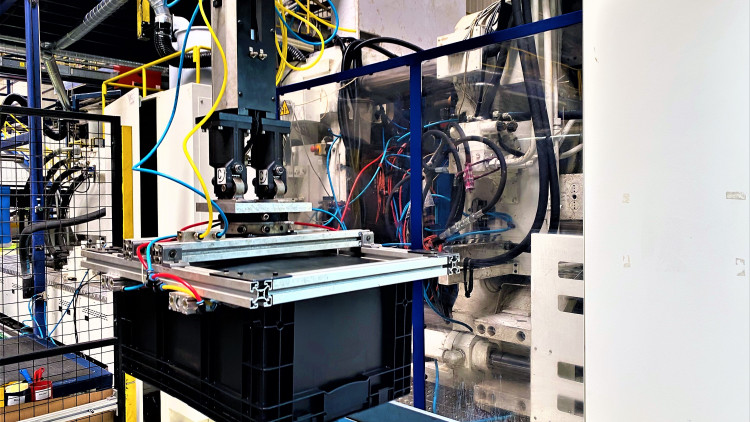

The raw material of plastic crates allows them to be produced in both white and various colors. The manufacturing process can be customized with optional coloring options. The plastic case raw material is polyethylene, which is a versatile type of thermoplastic. Its name comes from the monomer called ethylene, and ethylene is used to produce polyethylene. Polyethylene, simply called PE, is a term commonly used in the plastic industry.

The ethylene molecule has the formula C2H4 and is formed by the combination of two CH2 groups with a double bond (CH2=CH2). Polyethylene production occurs through polymerization of ethylene monomer. These polymerization methods include various methods such as radical polymerization, anionic polymerization, ion coordination polymerization and cationic polymerization. Each method allows the production of different types of polyethylene.

What Material Is Plastic Case Made With?

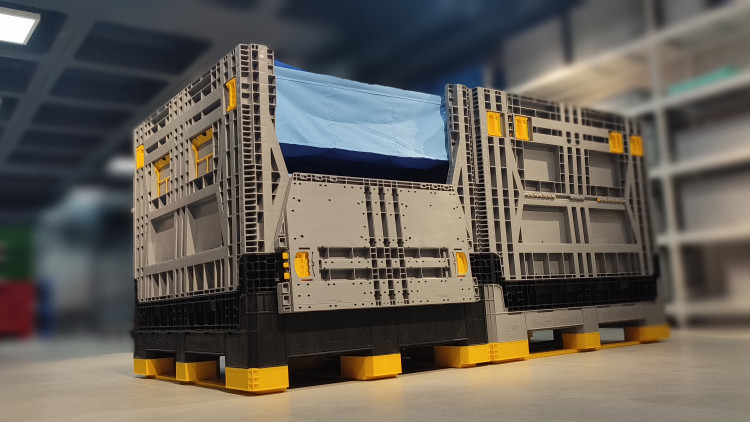

Its polyethylene-based production, which is a plastic case raw material, offers advantages such as durability, lightness and color options. The possibility of producing different sizes and designs, as well as color choices, is important in making plastic cases suitable for the needs of businesses and industries. Although the features of plastic cases vary according to different types, they generally have certain features. These properties include resistance to external influences and moisture, flexibility, low mechanical strength and resistance to chemicals.

Plastic crates have a wide range of uses; It is widely used in many areas such as containers, boxes, kitchen utensils, coatings, pipes and tubes, toys, insulating layers in cables, and packaging films. Additionally, offering a low-cost solution is among their advantages. Polyethylene is classified according to density and chemical properties. Mechanical properties vary depending on molecular weight and crystal structure.

Is Plastic Crate Raw Material Durable?

High Density Polyethylene (HDPE) is a type of polyethylene and is particularly known for its durability and strength. Polyethylene is a material that is extremely resistant to fatigue. In addition, it stands out with its low cost, impact resistance, low friction coefficient and strong electrical insulation properties.

It has good resistance to chemical effects and is suitable for a wide range of thermoplastic processing methods. Polypropylene has a melting temperature of around 160 degrees Celsius, which is particularly notable. However, it has some limitations. For example, it has limited resistance to UV rays and high thermal expansion. Painting and coating processes can be difficult. Likewise, its resistance to external weather conditions is limited and it is susceptible to oxidation.

It is a flammable material and can interact with solvents containing chlorine. Products made from this type of material are quite diverse. Examples include products such as detergent box covers and margarine containers. Thanks to its recyclability, it can also be used in the production of products such as synthetic carpet base, various plastic toys and stationery materials. Polypropylene is an important material for a wide range of industries and is preferred in different areas of use depending on its properties.