What is the contribution of plastic crates to saving costs?

September 25, 2023

In addition to the product's function, basic features and lifespan, one of the factors that most affects the sales potential is the cost of the plastic case. One of the most critical issues to be considered in plastic part design is cost. Considering the design, production and quality control stages, one of the biggest cost elements today is production.

Plastic part production costs generally consist of basic components such as raw material cost, mold design and production cost, production cost, marketing cost, employee costs and factory fixed expenses. Costs can generally be divided into two main categories: fixed and variable costs. Fixed costs are costs that exist continuously, regardless of the amount of production.

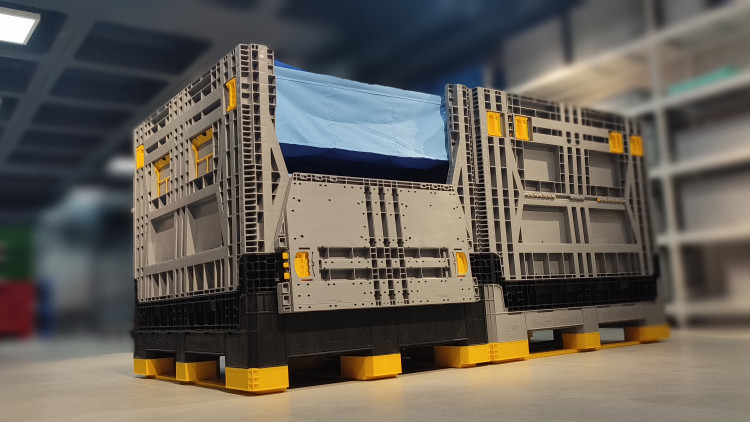

Cost of Plastic Crates

An example of this is building rent; Total fixed cost does not change whether the production amount increases or decreases. These expenses, also called administrative and operating general expenses, include general operating expenses such as rent, electricity, water, telephone and internet of the building in which the business operates. Product design refers to the process of developing any intermediate or final product. At the end of this process, the product is available in virtual or real prototype form.

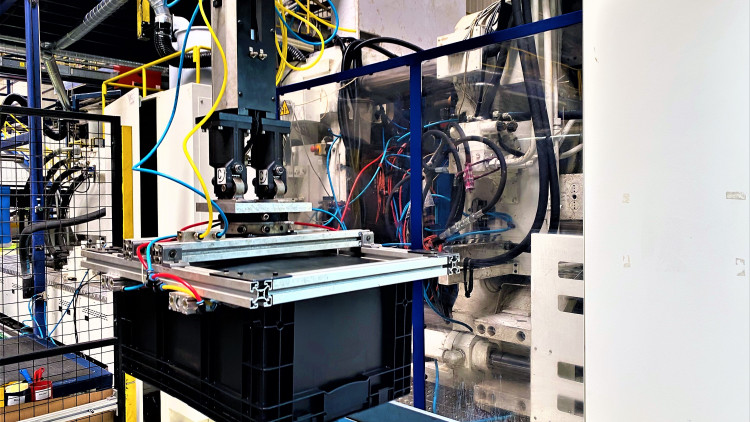

If a design that meets the specified requirements is created, the production phase begins. The main factors taken into consideration in the plastic case cost calculation are: mold cost (mold design and analysis, mold production), raw material cost, injection machine cost and operating costs (energy consumption, mold cooling cost, mold spare parts and maintenance, mold depreciation, injection machine spare parts and maintenance, injection machine depreciation).

A mold is a tool required to produce a plastic part quickly and in the same form every time. Before mold production, the design phase is carried out. One of the most important factors taken into consideration during mold design is the number of cavities in the mold and, depending on these cavities, mold filling, cooling processes and production cycle time.

Saving Money from Plastic Crates

As the number of cavities in the mold increases, the number of parts that can be produced per unit time increases and, accordingly, fixed costs and depreciation costs per product decrease. Likewise, a more efficient cooling system reduces the production cycle time and increases the number of parts produced per unit time. Products produced with minimal plastic case costs provide a great advantage in reaching potential customers or buyers.

In this process, where plastic part production consists of product design, production and quality stages, cost control and optimization plays an extremely critical role at every stage. Because these steps affect the final price of the product. Factors such as an ideal part design, the most suitable material selection, optimized mold design, and the most suitable machine selection are important factors that affect the cost of the product. In this way, plastic case production costs can be easily calculated.